Case Studies

From Chaos to Clarity — Transforming a Power Systems Manufacturer into a Market Leader

A power systems manufacturer producing uninterruptible power supplies (UPS) for traffic intersections was struggling to scale. Efficiency Edge helped rebuild its engineering foundation, streamline production, and grow revenue from $2M to $20M in just three years.

The Challenge

The company had a strong concept — using advanced Nickel-Zinc battery technology — but was held back by operational chaos:

- Annual revenue was about $2 million.

- 40% of products were being returned due to system and manufacturing failures.

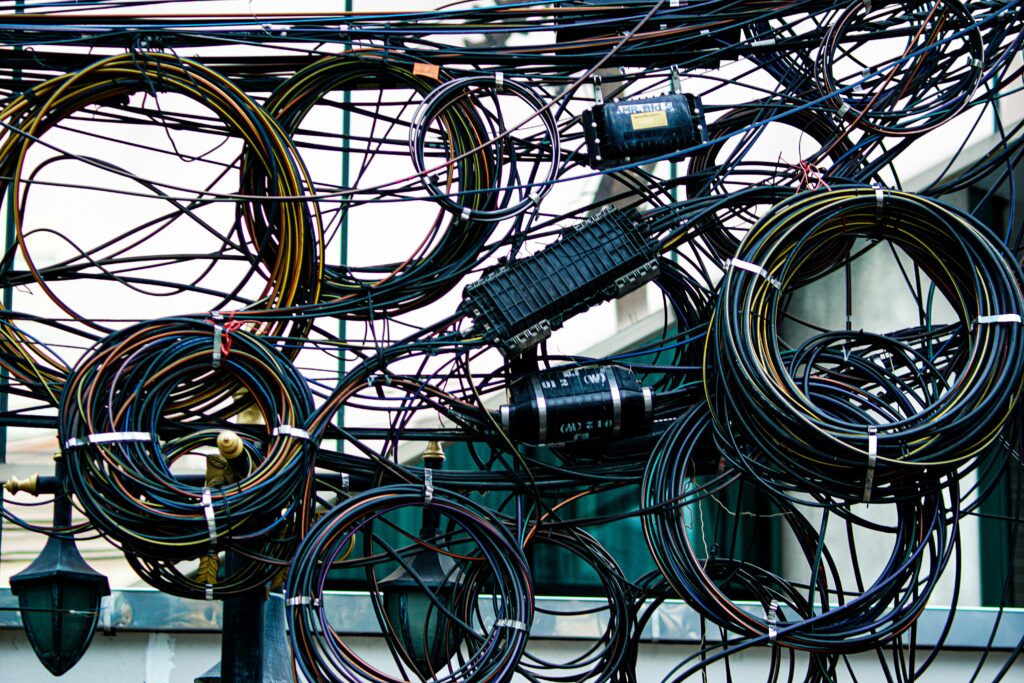

- Each unit took six hours to assemble and required extensive manual wiring.

- Engineering tools were outdated, documentation was nonexistent, and no project management systems were in place.

- Key roles had been filled based on familiarity rather than capability.

The company had a promising product but lacked the systems, processes, and team structure to grow.

The Intervention

When I joined the leadership team, I began by diagnosing the root causes — not just in the product, but in how work was organized and decisions were made.

I presented the findings to the executive team and proposed a complete redesign of both the product and the operational systems behind it.

Together, we:

- Rebuilt the engineering team, hiring experienced electrical and software engineers with deep expertise in power systems.

- Implemented Confluence and Jira to centralize documentation, manage development, and onboard new hires.

- Invested in modern design tools (Altium) and brought in professional mechanical design support.

- Introduced Test-Driven Development (TDD) for embedded software, achieving 100% code coverage and eliminating recurring bugs.

- Established clear engineering standards, root cause analysis procedures, bug tracking, and onboarding playbooks to support sustainable growth.

These steps not only solved the immediate problems but built a foundation for scale.

The Transformation.

The turnaround was remarkable.

| Metric | Before | After |

|---|---|---|

| Product build time | 6 hours | 20 minutes |

| Product return rate | 40% | 1% |

| Development cycle | 12 months | 6 months |

| Annual revenue | $2M | $20M (in 3 years) |

The redesigned product earned national acceptance and was added to state-approved equipment lists followed by Departments of Transportation across the U.S. Manufacturing became streamlined and predictable, and the company shifted from firefighting problems to scaling strategically.

The Takeaway.

Sustainable growth doesn’t come from working harder — it comes from building systems and teams that make excellence repeatable. By combining disciplined engineering processes, data-driven problem solving, and strategic hiring, we transformed a struggling operation into a scalable, profitable enterprise.

That’s what Efficiency Edge helps business owners do every day.