If your business is constantly putting out fires, automation will not save you. In fact, it may accelerate the chaos. Before you add software, AI, or automations to smooth out the work, you need something far more fundamental: a clear, accurate map of how the process actually works today. I saw this firsthand with a pool service company losing customers and cash simply because no one understood the true flow of their service process. What happened next changed everything.

Before You Automate: Map the Process First

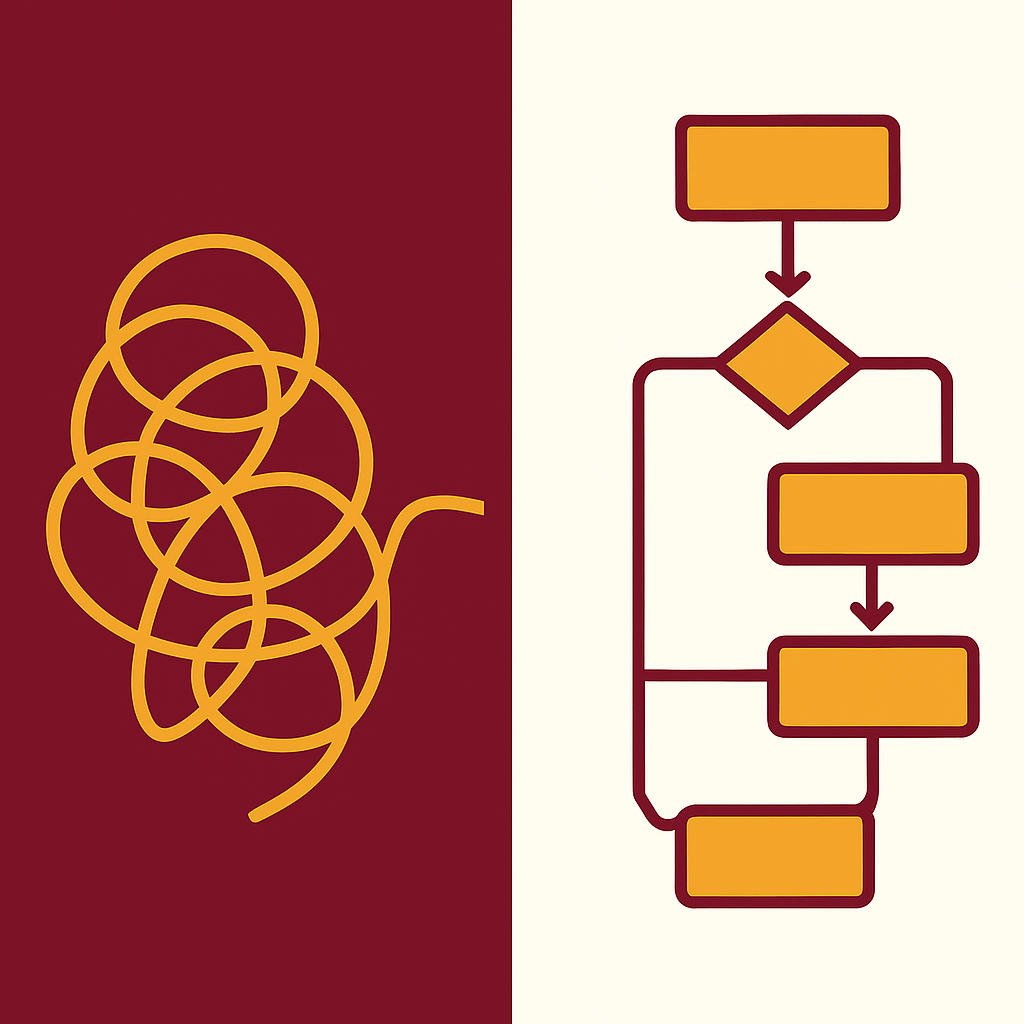

Automation promises efficiency, speed, and consistency, but only when it is built on stable ground. Too often, companies rush to automate broken processes. They add software to compensate for confusion, introduce tools without clarity, and hope technology will magically solve operational challenges. What they discover is the opposite. Automation amplifies whatever exists, good or bad.

This is why process mapping is not a nice-to-have step. It is the foundation. And nothing illustrates that more clearly than a recent engagement I had with a pool service company struggling with service failures, late jobs, inconsistent communication, and slow collections.

The Real Problem Wasn’t Labor or Software, It Was Invisible Work

When I first met the owners, they believed they had a people problem. Technicians were missing steps. Office staff were overwhelmed. Customers were frustrated. And revenue was slipping through the cracks. The instinct was to buy a new software tool that could automate scheduling, reminders, and billing so the business could stay on track.

But after listening carefully, it became clear that automation was not the cure. The real problem was that no one truly understood the flow of work. Everyone handled tasks differently. Information was scattered across texts, emails, handwritten notes, and memories. There was no standard process to automate.

So we paused the software search and held a mini kaizen event instead.

The Power of Mapping What Is Really Happening

A kaizen event, even a short one, forces the team to slow down and see the truth. We brought together everyone involved in serving a customer: the office manager, technicians, scheduler, and the person responsible for collecting payments.

Together, we mapped out the entire customer journey from the first phone call to final payment. Post-it notes filled the wall. At first it looked chaotic, but clarity slowly emerged.

Here is what we discovered:

1. No one had the same understanding of the process.

The office believed technicians were documenting findings at the job site. Technicians believed the office already had the information and did not need it repeated. This created gaps that customers felt immediately.

2. Parts were constantly delayed because ordering relied on memory.

By the time someone realized a part was needed, the job was already behind schedule. Customers waited, work stalled, and the company looked unreliable.

3. Collections only happened at the very end.

The company asked for payment once, at the hardest point to collect. Thirty, sixty, even ninety days passed before money came in.

4. Everyone had created their own workaround.

Technicians kept notes on their phone. The office kept notes in a binder. The owner kept notes in email. None of these connected.

No automation tool can fix what a process map reveals. But a process map makes fixing it possible.

Redesigning the Process to Reduce Failure Points

Once the whole team saw the real flow of work, the solutions became obvious. We redesigned the service process step by step, removing unnecessary tasks and making responsibilities unmistakably clear.

Some of the biggest improvements included:

A standardized intake process.

Every customer call captured the same information in the same way, ensuring technicians had what they needed before arriving on-site.

A defined parts ordering system.

Instead of relying on memory, we built an early identification step where techs flagged what parts were needed before leaving the job. This triggered immediate ordering and prevented delays.

Multiple built-in collection points.

By adding payment requests earlier and more often, cash flow increased without adding pressure to the team.

A simple shared workflow visible to everyone.

Once the process was mapped and streamlined, it became easy to choose the right tool to manage it. Automation was added to support the process, not to compensate for its weaknesses.

Within weeks, the company saw fewer service failures, faster turnaround times, and a noticeable improvement in customer satisfaction. Most importantly, cash flow stabilized because work moved predictably.

Automation Works When Your Process Works

This experience is not unique. I see it constantly in manufacturing, distribution, construction, engineering, and service industries. A company buys automation technology before mapping the process, only to find that the root issues get worse.

Here is the truth:

Automating a broken process does not make it efficient.

It makes it break faster.

Process mapping serves three critical purposes before automation:

1. It exposes the real work, not assumptions.

Most leaders believe they know how work is done. A map shows what is actually happening.

2. It removes waste before technology locks it in.

Software tends to institutionalize whatever exists. By removing waste first, you automate only what adds value.

3. It builds clarity and accountability.

Everyone sees where handoffs occur, who owns each step, and where failures are likely.

Only after you have a clean, stable process does automation give you the efficiency gains you expect.

If You Want Efficiency, Start With a Marker and a Wall

Businesses often look for the big solution: a new platform, an automation tool, or AI. But the biggest improvements usually come from making the existing work visible.

A process map turns scattered, inconsistent effort into a clear, unified system that everyone can follow. Then automation becomes a force multiplier instead of a bandage.

If your operations feel chaotic or unpredictable, do not start with technology. Start with mapping.

Automation is powerful, but only if you understand what you are automating.